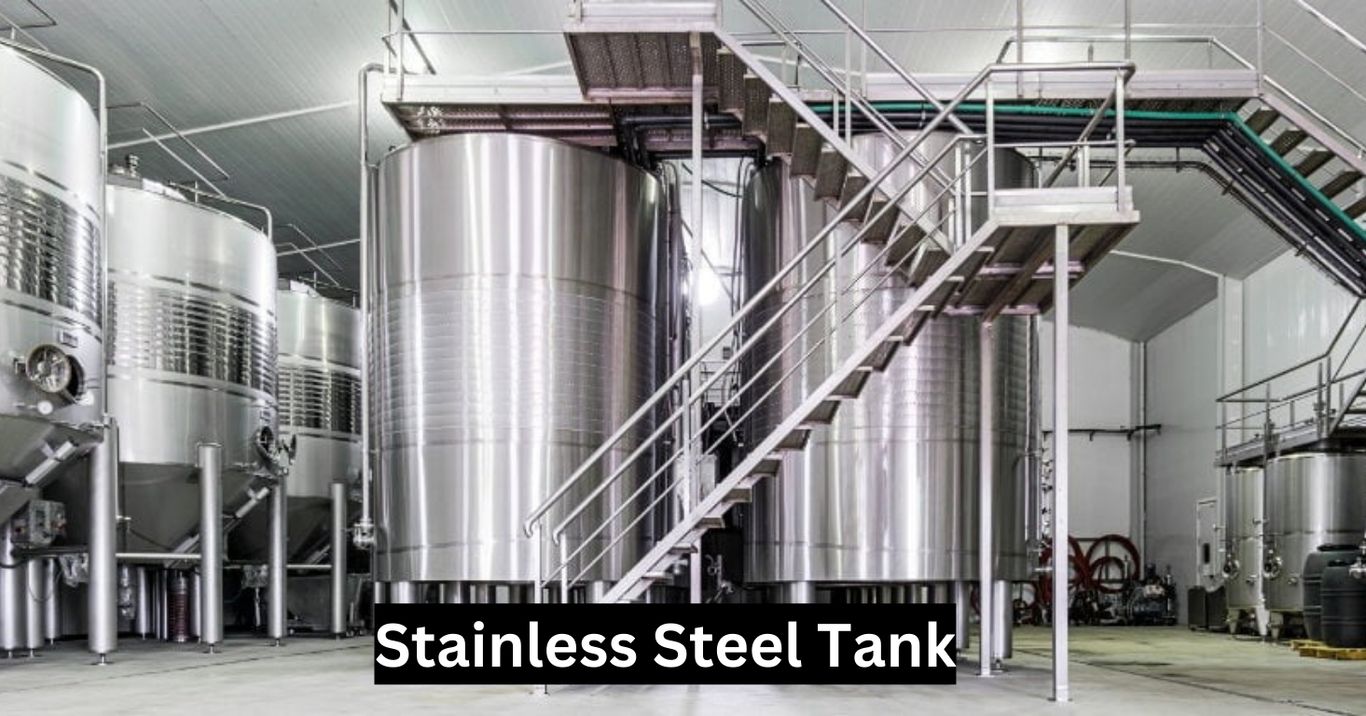

Stainless steel tanks are integral to numerous industries, serving diverse purposes ranging from storage to transportation of liquids, gases, and chemicals. Their durability, resistance to corrosion, and adaptability make them a preferred choice in industrial, commercial, and even residential settings. This comprehensive guide explores the benefits, types, applications, and maintenance of stainless steel tanks, ensuring an SEO-friendly yet engaging narrative.

What Are Stainless Steel Tanks?

Stainless steel tanks are containers made from stainless steel, an alloy known for its corrosion resistance and strength. These tanks come in various shapes, sizes, and configurations, tailored to specific applications. Their versatility has made them a cornerstone in industries such as food processing, pharmaceuticals, chemical manufacturing, and water treatment.

Key Benefits of Stainless Steel Tanks

1. Corrosion Resistance

One of the standout features of stainless steel is its exceptional resistance to rust and corrosion. The chromium content in stainless steel forms a protective oxide layer, safeguarding the tank from environmental and chemical damage.

2. Durability and Longevity

Stainless steel tanks can withstand extreme temperatures, high pressure, and heavy usage, making them a cost-effective investment for industries seeking long-term solutions.

3. Hygienic Properties

Thanks to their smooth surface, stainless steel tanks are easy to clean and maintain, ensuring compliance with stringent hygiene standards in the food and pharmaceutical sectors.

4. Eco-Friendly and Recyclable

Stainless steel is a sustainable material that is 100% recyclable, making it an environmentally friendly choice.

5. Aesthetic Appeal

In settings where appearance matters, such as breweries or residential use, stainless steel tanks provide a sleek, polished look.

Types of Stainless Steel Tanks

1. Storage Tanks

These are used for storing liquids like water, chemicals, and food products. Storage tanks can be vertical, horizontal, or cylindrical based on specific needs.

2. Mixing Tanks

Designed with agitators, these tanks are used to mix or blend liquids, commonly found in the food, beverage, and pharmaceutical industries.

3. Process Tanks

Used in manufacturing processes, these tanks often come with heating or cooling systems to facilitate chemical reactions or fermentation.

4. Transport Tanks

Engineered to transport liquids safely, these tanks are used in industries like oil and gas, dairy, and chemicals.

5. Custom Tanks

Tailored for unique applications, custom tanks can vary in size, design, and additional features like insulation or multi-compartment systems.

Applications of Stainless Steel Tanks

1. Food and Beverage Industry

Stainless steel tanks play a critical role in the production, storage, and transportation of food and beverages. Their non-reactive nature ensures the preservation of flavor and safety.

2. Pharmaceutical and Cosmetic Industries

In these highly regulated sectors, stainless steel tanks are used to store and process materials, meeting hygiene and sterility requirements.

3. Water Treatment

From potable water storage to wastewater treatment, stainless steel tanks are essential for maintaining water quality and managing large volumes.

4. Chemical Industry

These tanks are designed to resist chemical reactions, ensuring safe storage and processing of hazardous substances.

5. Oil and Gas

Stainless steel tanks store and transport petroleum products, offering durability and leak-proof solutions.

Factors to Consider When Choosing a Stainless Steel Tank

1. Material Grade

Stainless steel comes in various grades, such as 304 and 316, each suited to specific applications. Grade 316, for example, offers higher corrosion resistance and is ideal for marine or chemical environments.

2. Capacity

Tanks are available in capacities ranging from a few liters to thousands of gallons. Choose one based on your volume requirements.

3. Configuration

Consider the tank’s design, such as vertical or horizontal orientation, based on your space and operational constraints.

4. Additional Features

Depending on your needs, you might require tanks with insulation, heating jackets, or agitators.

5. Compliance and Certification

Ensure the tank meets industry standards and certifications like FDA, ASME, or ISO for specific applications.

Maintenance Tips for Stainless Steel Tanks

1. Regular Cleaning

Clean tanks periodically with appropriate cleaning agents to prevent residue buildup and maintain hygiene.

2. Inspect for Damage

Regularly inspect for signs of wear, such as dents or scratches, which can compromise the tank’s integrity.

3. Protective Coatings

For tanks exposed to harsh chemicals or environments, consider applying protective coatings.

4. Avoid Abrasive Materials

Use non-abrasive cleaning tools to prevent scratches and maintain the tank’s surface finish.

5. Monitor Seals and Fittings

Inspect seals, gaskets, and fittings to ensure they remain intact and functional.

Innovations in Stainless Steel Tank Technology

1. Smart Tanks

Modern tanks come equipped with sensors to monitor liquid levels, temperature, and pressure in real-time, improving operational efficiency.

2. Advanced Coatings

Innovative coatings enhance corrosion resistance, especially in environments with highly aggressive chemicals.

3. Custom Fabrication

Advances in fabrication technology allow for highly customized tanks, tailored to specific operational needs.

(FAQs)

What are stainless steel tanks used for?

Stainless steel tanks are used for storing, processing, and transporting liquids, gases, and chemicals in industries like food and beverage, pharmaceuticals, chemicals, and water treatment.

What makes stainless steel tanks better than plastic or other materials?

Stainless steel tanks are more durable, corrosion-resistant, environmentally friendly, and capable of handling extreme temperatures and pressures compared to plastic or other materials.

What grades of stainless steel are commonly used for tanks?

The most commonly used grades are 304 and 316 stainless steel. Grade 316 offers superior corrosion resistance, especially in harsh chemical or marine environments.

Are stainless steel tanks safe for food and drink storage?

Yes, stainless steel is non-reactive and safe for food and beverage storage, meeting hygiene and safety standards in the industry.

How long can a stainless steel tank last?

With proper maintenance, stainless steel tanks can last for decades, often outliving other types of tanks.

Maintenance and Cleaning

How do I clean a stainless steel tank?

Use non-abrasive cleaning agents and tools to prevent scratches. Regularly clean the tank to remove residue and maintain hygiene.

Can stainless steel tanks rust?

Stainless steel is highly resistant to rust due to its chromium content. However, prolonged exposure to certain harsh chemicals or damage to the protective oxide layer can lead to localized corrosion.

Do stainless steel tanks require regular inspections?

Yes, regular inspections are essential to check for damage, wear, or residue buildup and ensure the tank operates efficiently.

What should I avoid when cleaning stainless steel tanks?

Avoid using abrasive cleaning materials, harsh chemicals like bleach, or tools that could scratch the surface.Can

dents or scratches in stainless steel tanks be repaired?

Minor dents or scratches can often be repaired, but extensive damage may require professional restoration.

See Also: techinfomagazine.com

Conclusion

Stainless steel tanks are an indispensable asset across various industries, offering unmatched durability, hygiene, and versatility. Their ability to withstand challenging conditions while maintaining functionality makes them a top choice for businesses and individuals alike. Whether you’re in the food industry, water treatment, or chemical processing, investing in a stainless steel tank ensures long-term reliability and efficiency.

By understanding their benefits, applications, and maintenance needs, you can make informed decisions that align with your operational requirements. Stainless steel tanks are more than just containers—they’re an investment in quality and sustainability.